VIRTUAL TOUR 360°

Since its foundation, Spanopoulos shipyard has developed major capabilities in dry docking, ship construction, repair and conversion. The company operates as an independent unit and pursues its own activities based on its particular qualifications, assets equipment and facilities.

Our fully equipped shipyard unit, of approximately 100.000 sq.m, is located in Ampelakia on the island of Salamis, Greece.

Dock position / coordinates: 370° 57’ 13’’ N - 230° 33’ 06’’ E.

There are dedicated zones for hauling - docking - repairing - long period staying of yachts and various workboats and for building, converting, repairing and maintenance of vessels and any type of floating equipment.

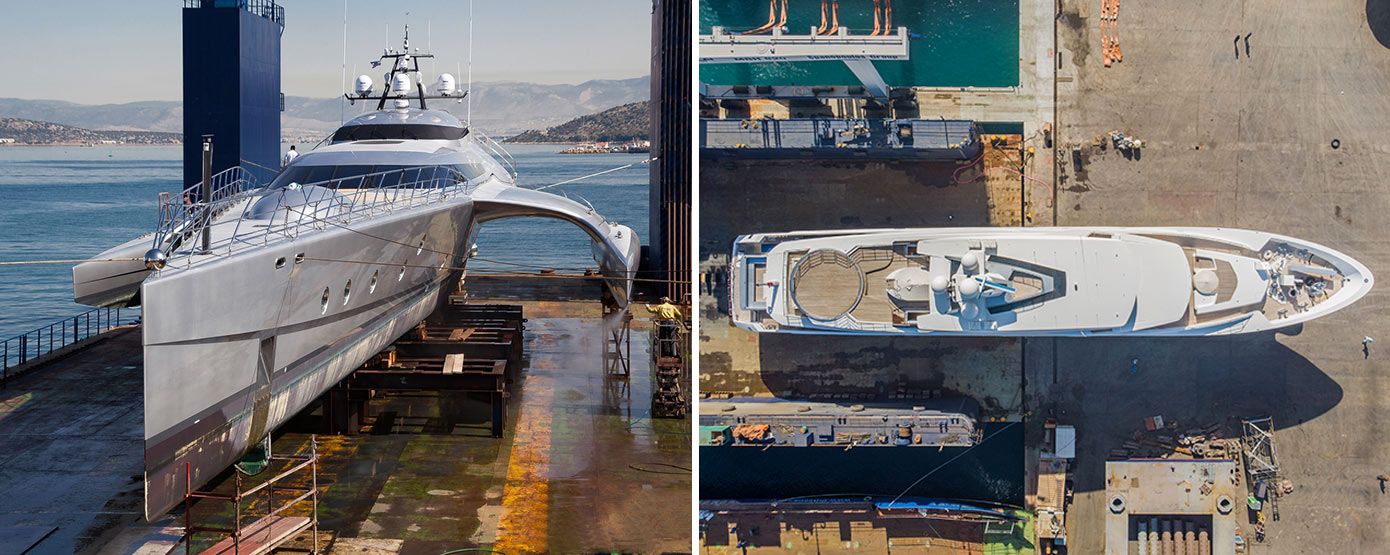

HAULING & LAUNCHING SERVICES

The shipyard facilities can accommodate ashore more than 30 vessels of various lengths, up to 120m, and approximately 30 moored boats up to 240m. We may also provide a 5,000 tons floating dock of 100m length, 28.60m width, 3.60m height and two Kamag type boat trolleys able to transfer vessels of length up to 100m and displacement of up to 2,500t.

In the frame of our development program we recently acquired a 22,500 tons floating dock of 232m length and 34m net breadth.

We own an ultra-modern, 820 tons Mobile Boat Hauler for the hauling of yachts - vessels that have a maximum length of 80m, as well as a 300 tons Mobile Boat Trolley for the transportation of the vessels inside the shipyard.

Our shipyard handles all shipbuilding & repair services, as well as the upgrading of our clients' fleets, under the guidance and supervision of our naval architects, mechanical engineers and electrical engineers of our in house technical department.

NEW BUILDINGS

Spanopoulos Shipyards have undertaken the construction of new vessels for domestic and foreign customers as well. We have competed successfully the new building of workboats, tugboats, barges, etc. for our, group owned, fleet and for other clients.

Significant projects are being executed at our premises including the construction of four Auxiliary Boats for the Hellenic Navy, a work boat and an Antipollution Barge for foreign clients, built under high quality standards and close supervision.

REPAIR SERVICES

Our services are very broad ranging from basic maintenance to complete refit and extensive repairs of most kinds of vessels, using up to date technologies and processes, complete refurbishment, interior design - decoration, antifouling, mechanical works, several surface preparation techniques, painting works.

TECHNICAL WORKSHOPS

- Machine shop

- Electrical shop

- Carpentry

- Plate shop

- Pipe shop

Provision of a versatile range of services:

- Hauling, launching, dry docking, short - term stays and wintering

- Constructions, reconstructions, conversions, general repairs

- Repairs, renewals, placement of steel plates and aluminum constructions

- Hydro blasting, high-power water jetting (400 – 3000 bar), sand blasting, slurry blasting

- High quality painting, surface treatment, steel-plate rust removal

- Piping, mechanical, electrical, engine and auxiliary machinery works

- Shafting and propeller works

- Repair of valves

- Replacement of anodes

- Scaffolding, shrink wrap

PROVISIONS AND SUPPORTING FACILITIES:

- Conference and seminar rooms

- Hangar for new buildings and prefabrications in covered area

- 2 new hangars under construction of total area 3.500sqm with modern equipment, gantry cranes, etc., for various workshops and supporting offices

- Technical support from our highly-specialized and trained personnel (Naval Architects, Mechanical Engineers, Electrical Engineers, Safety Engineers, Marine Chemists)

- Issuance of Gas Free Certificates

- Ultrasonic Thickness Measurements

- Performance of Non-Destructive Tests

- Fire-fighting line supply system

- Compressed air supply system

- Ventilation supply system

- Electric power supply system (380, 220, 110, 42, 24 V)

- Fully equipped Piping workshop

- Three (3) Automatic CNC cutting machines guided by special software program. Uses oxygen & acetylene, plasma for aluminum and other specific materials

- Various plate shop equipment like presses, rollers, etc.

- Fully equipped machine shop

- Welding Machines for MIG, MAG, TIG, MMA methods operated by certified welders

- Containers for offices and stowage

- Tower cranes of 20 tons

- Forklifts, cherry pickers, scissor lift, telescopic cranes

- ISO Box Offices

- Wireless Internet

- Close Circuit TV system

- Security Guard (on 24hrs basis)

DESIGN DEPARTMENT

Our in-house Design Department is mainly comprised of Naval Architects-Marine Engineers. The construction experience and continuous development of our department, has led us to the position of being able to provide a wide range of services from basic design to detailed workshop drawings. Apart from our engineering capacity, all projects are handled by our competent ship repair managers, applying modern project management techniques offering strict supervision and turnkey solutions.

QA/ HSE MANAGEMENT SYSTEMS

New Hellenic Shipyards has developed, implements and maintains a Quality and Environmental Management System (QMS & EMS) that meets the ISO 9001:2015, ISO 14001:2015 and OHSAS 18001:2007 requirements and forms part of the Company’s Integrated Safety, Quality and Environmental Management System (SQEMS), in a way to demonstrate the Company’s ability to consistently provide services that meet and exceed customer requirements and applicable regulatory requirements, commitment to continual improvement, environmental excellence and environmental responsibility. The Company has been certified to ISO 9001:2015 (Quality Management System Standard) by ABS Quality Evaluations, ISO 14001:2015, (Environmental Management System Standard) and OHSAS 18001: 2007 (Occupational Health & Safety Management System) both by LRQA.